Quality Checklist for Industrial Coatings

Quality is of the utmost importance when it comes to industrial coatings. Crest Coating specializes in industrial powder, Teflon, and liquid coatings. Our highest priority is consistent quality and exceeding our customers’ most demanding requirements.

Meeting this goal requires the latest in inspection and quality assurance equipment. Below is a checklist of the tools and measures we use to ensure quality coatings.

Spectrophotometer

A spectrophotometer is a color measurement tool commonly used for the measurement of reflectance of opaque solids. Photometers measure a light beam’s intensity as a function of its color (wavelength). This helps us check the quality of our coatings by ensuring the correct concentrations of each chemical ingredient.

In-House Salt Spray (Per ASTM-B117)

Salt Spray Testers are closed cabinets that continually introduce a saltwater (5% NaCl) solution to parts via a mist or fog. Spray nozzles atomize the saltwater with pressurized air, accelerating a corrosive environment for test parts. A spray test makes sure that our coated parts will not corrode and are ready for harsh environments.

Datapaq Oven Profiler

The Datapaq® profiler offers robust, comprehensive, intelligent, and easy-to-use oven temperature profiling. The software converts raw temperature data into meaningful information that can be used to optimize the cure process. This improves quality by ensuring our coatings are cured at the exact right temperature.

Bend & Mandrel Testers

A Bend Test curves coated metal sheets over a cylindrical or conical mandrel to observe if the coating develops cracks or discoloration. A conical mandrel tester is used in the determination of elasticity, adhesion, and elongation of paint on sheet metal. This is a stress test of our coatings to ensure they will not easily crack or break.

Impact Testers

Impact testers use either a weight with a hemispherical punch falling on a coated metal sheet or a weight falling onto a hemispherical punch resting on a coated metal sheet. The weight is lifted to a predetermined height, released, and the deformation is observed. Our coatings are only approved if they can withstand impact.

Psychrometer Hpot® Tester

A psychrometer is a type of hygrometer, or humidity gauge. A psychrometer measures the relative humidity in the atmosphere through the use of a dry bulb thermometer to measure air temperature and a wet bulb thermometer to measure temperature in a liquid. This tool ensures optimal conditions for creating our coatings.

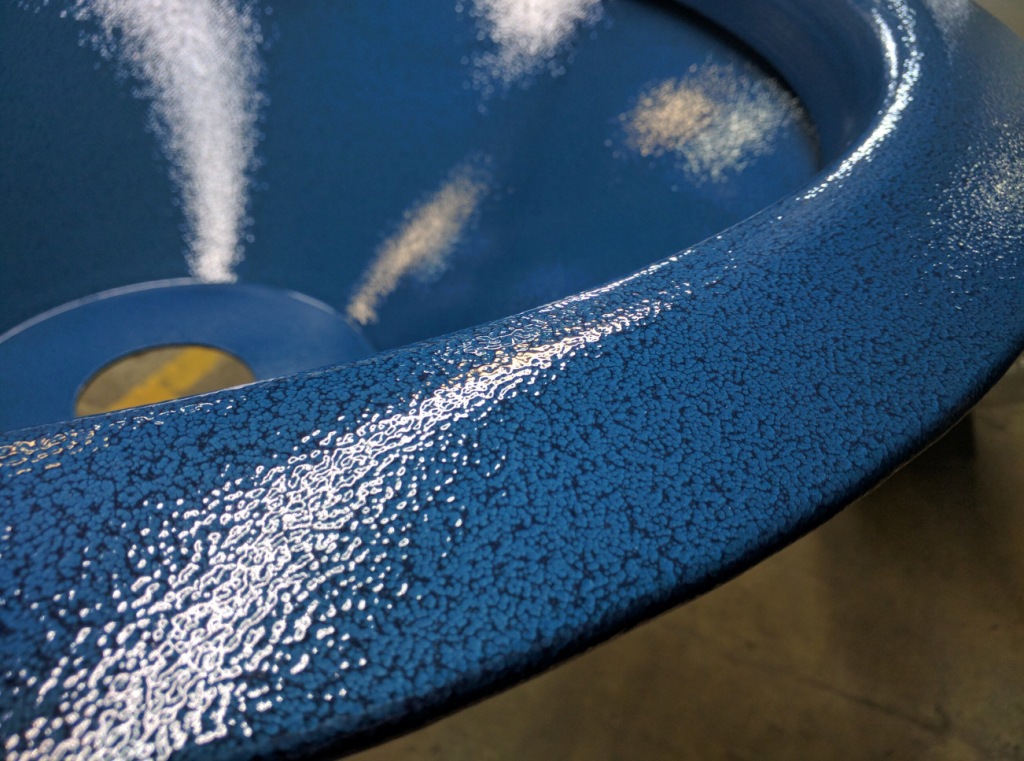

Profilometer

A profilometer measures a surface’s profile in order to quantify its roughness. Dimensions such as step, curvature, and flatness are computed from the surface topography measured through the device. This is typically used for powder coatings to ensure the textured surface of the coating is suited for its application.

Laser Temperature Measurement

A laser helps aim either a non-contact thermometer, often infrared, to measure temperature from a distance. These thermometers offers an easy and safe method to measure surface temperatures of objects that are difficult or unsafe to contact. We use laser temperature measurement to ensure optimal conditions during manufacturing.

Thickness Gauges: Magnetic, Eddy Current, or Tooke Gauge

Thickness testers use different technologies to gauge the consistency of coating quality across an entire coated surface. These tools reduce excess coating waste and prevent reworks caused by either too much or too little coating.

Gloss Meter

Gloss meters evaluate glossy coated surfaces with an infrared source that emits a beam of light at an angle to the surface. A sensor measures the reflected light and delivers a numerical value to the gloss profile. This makes sure our coating surfaces are suited for their end applications.

At Crest Coating, we value the extensive coating and application knowledge of our staff, who have decades of experience. To find the right coating for your next project, fill out this quick form today.