Microchip Manufacturers Rely on High-Purity Coating

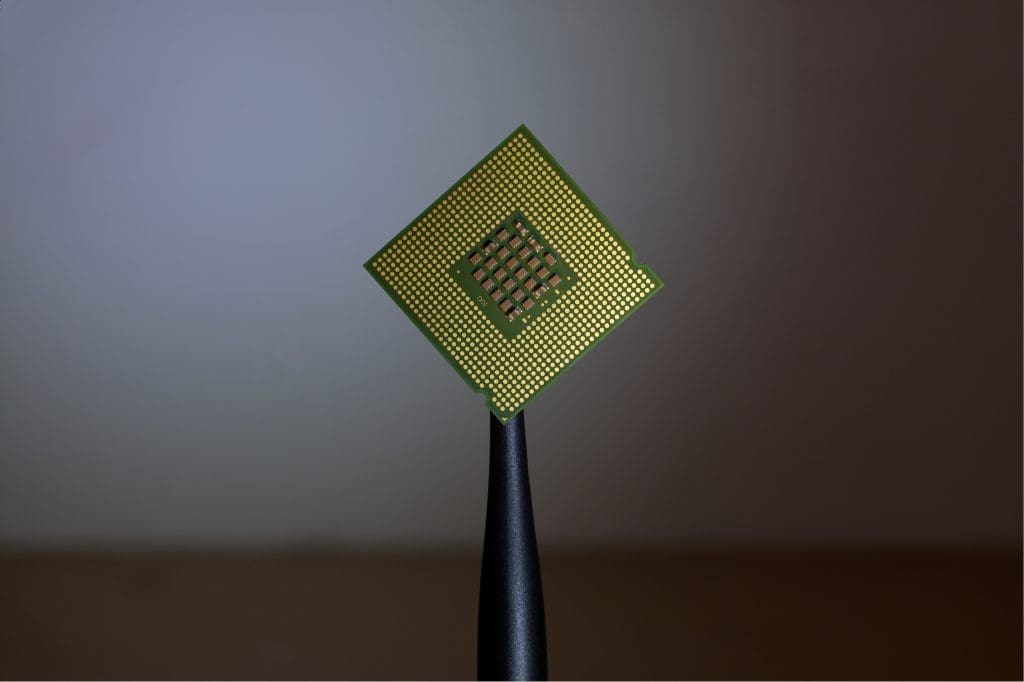

As microchip sizes shrink, the threat that microscopic contaminants have on their performance increases. That’s where high-purity coating comes in. Cleanliness is everything in the semiconductor industry as contaminants are measured in micrometers. A contaminant can be anything from a particle of dust to moisture in the air.

With Semiconductors, Small Contaminants Matter

High-purity coating technology around has advanced hand in hand with the semiconductor industry to enable cleanrooms to become cleaner and produce better microchip yields. Clients come to Crest Coating with increasingly more stringent requirements for high-purity and corrosion-resistant coatings that can maintain the integrity of factory cleanrooms.

These coatings are absolutely necessary for any components that will be used in the process of making microchips and other sensitive computer components. The rigorous cleaning and re-cleaning that equipment undergoes is enough reason for corrosion-resistant coatings. On top of this, uncoated surfaces can shed particles with wear and tear, oxidize, and be hard to decontaminate.

Whenever parts are sent to us needing high-purity corrosion-resistant coatings, we assume they might be used in a cleanroom environment. That is the standard to which we hold ourselves.

How to Pick the Right High-Purity Coating

What makes a coating high-purity is that it ensures that microscopic particles of the coating don’t break free and contaminate the air. It takes more than simply being high-purity to endure the process of producing microchips. For use in the semiconductor industry, you also need to pick a coating that can withstand other environmental factors like:

- What cleaners are used between manufacturing steps

- The chemicals used in manufacturing

- Duration of exposure

- Operating temperature

- Possibility of abrasion

Fluoropolymers such as Teflon™ coatings and Xylan® coatings, and the use of Thermoplastics like the ones produced by Halar are well-recognized names in the semiconductor industry for their qualities. They are very popular in cleanroom environments due to their various benefits:

- Anti-coking and anti-biofouling – The surface is resistant to carbon or microbial build-up.

- Abrasion resistance – The surface is tough and won’t accumulate scratches.

- Contamination resistance – The surface will not absorb contaminants.

- Easy cleaning – The surface is resistant to corrosion and releases contaminants easily.

- Hydrophobicity/Oleophobicity – Water-based and oil-based contaminants are repelled.

What Surfaces Need a High-Purity Coating

If your equipment is to be used in a cleanroom, It should be coated with an abrasion-resistant, high purity, and corrosion-resistant coating. When contaminants are measured in micrometers, no chances should be taken. Metals can oxidize and shed particles, ruining product batches. Non-abrasion-resistant equipment can deteriorate and chip. Protect your equipment and your products and use coatings to improve your yields and ensure durability.

Manufacturers of microchips and other computer parts err on the side of caution when deciding what to coat. Sure, composite surfaces like silicon carbide are corrosion resistant and could go uncoated for some time but opting to go with a high-purity and highly corrosion resistant fluoropolymer coating offers the ongoing benefits of ease of cleaning and maintenance.

A High-Purity Coating Needs Skilled Application

Take no chances with the quality of your equipment by working with an expert team. At Crest Coating, our in-house capabilities and expertise has earned us several certifications that qualify us for your High-Purity Coating needs.

We are ISO Certified, which means that we have established a set of standard practices to ensure that we perform the same steps, with the same precision, each and every time. The coating you use can be just as important as the equipment being coated when it comes to professional coatings.

Furthermore, our certification as a Chemours Licensed Industrial Applicator proves our skill and experience in applying a wide variety of Chemours Teflon™ coatings. From bakeware to cleanrooms, we can help you identify which coating will best suit your needs.

Trust Us with Coating Your Cleanroom Equipment

Crest Coating, Inc., established in 1967, has unsurpassed experience and knowledge in industrial powder coating services and exotic liquid coatings. For over 40 years, we have retained the status of Chemours Licensed Industrial Applicator and Approved Applicator for Whitford Xylan®, Halar®, BCS Technologies, and other exotic coatings. We have experience working on complex projects and provide expertise and support for any of our clients’ needs.

At Crest Coating, we value the extensive coating and application knowledge of our staff, who have decades of experience. To find the right coating for your next project, fill out this quick form today, or contact one of our experts by calling 714-635-7090.