How Do Antimicrobial Coatings Work?

Antimicrobial Coatings: Germ Growth Protection in High-Traffic Spaces

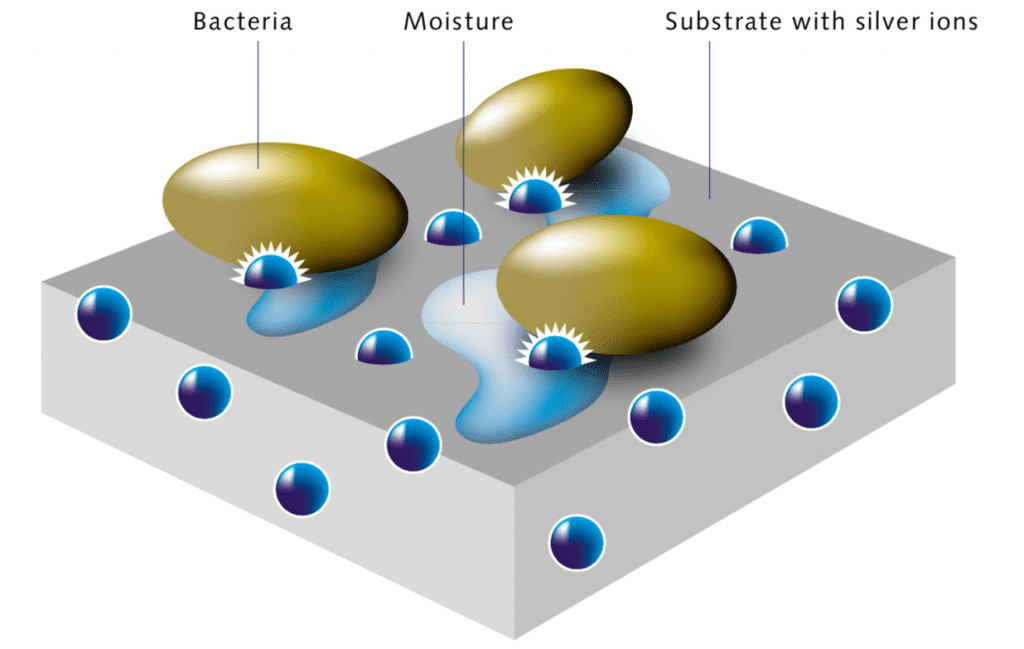

Additives such as silver ions inhibit germ growth.

Antimicrobial coatings are able to prevent germ growth for many applications well beyond healthcare. These are durable coatings that can continue to perform even through regular, repeated water exposure and cleaning.

According to research at MarketsandMarkets, antimicrobial coatings are projected to become a requirement in high-traffic buildings of all kinds in the coming years. Academic environments, offices, and healthcare institutions will have more surfaces coated with antimicrobial agents as well as indoor air-conditioning and HVAC systems:

“Medical is anticipated to be the fastest growing application segment during the forecast period. Antimicrobial coatings are used in medical products, devices, and surfaces in medical facilities to prevent the spread of infections. The medical application also accounted for the largest share of the overall antimicrobial coatings market and this trend is projected to continue throughout the forecast period.”

Our Preferred Antimicrobial Coatings Contain Silver Ions

At Crest Coating, we prefer antimicrobial coatings that contain silver ions, which have long been used to inhibit germ growth and “inactivate” bacteria. Here we’ll look at two prominent suppliers and the features of their antimicrobial coatings. One is a Swiss-based partnership and one is Pennsylvania-based.

Sanitized Brand and IGP-DURA®care Antimicrobial Coatings

IGP Powder Coatings and the Sanitized brand are both Switzerland-based companies that supply a wide variety of functional coatings. They supply antimicrobial coatings frequently to prevent bacteria growth in medical technology, healthcare, and geriatric care.

IGP’s coating systems are used for medical equipment and furniture as well as in many other sanitary applications. In independent testing, numerous test bacteria including multi-resistant bacteria were verifiably reduced within a very short time by up to 99.9 %. Their main two product lines are:

- IGP-DURA®care 32: Characterized by the excellent chemical resistance and its anti-microbial function.

- IGP-DURA®care 68: For long-term, efficient protection against microbial contaminations from a curing temperature of 150°C.

Using silver ions as a permanent material component prevents strong germ growth between cleaning cycles and guarantees low bacterial attack for many years. Successfully fighting germ growth consists of three action mechanisms: 1) blockage of primary cell metabolism; 2) stoppage of cellular respiration; and 3) prevention of cell division. These three mechanisms prevent the growth of undesired microorganisms on surfaces. The substance combination is activated by moisture and develops its antimicrobial effect. Existing bacteria are continuously inactivated through the Sanitized® hygiene function. This means the surface is kept clean.

Alesta® AM Brand Antimicrobial Coating

Axalta Coating Systems is based in Glen Mills, PA, and promotes Alesta® AM as a patented powder coating solution treated with silver ion or silver zeolite technology. These coatings provide corrosion protection to high traffic areas, most often in healthcare environments and school facilities.

Alesta AM inhibits the growth of microbes on powder coated surfaces and is available in epoxy, hybrid, and polyester forms as well as in a full range of colors, textures, and glosses. These coatings also provide corrosion protection that is ideal for hospitals, public transit, restaurants, park and playground structures, medical equipment, water treatment plants, food service packaging equipment, pharmaceutical labs, and school and childcare facilities.

Some Alesta AM powder coatings can be formulated to meet FDA guidelines under the Federal Code of Regulations, Title 21, Section 175.300; Resinous and Polymeric Coatings and the NSF/ANSI Standard 51 for food equipment materials. Custom formulations are also available to fit your exact needs for antimicrobial powders.

Decades of Experience

At Crest Coating, we pride ourselves on solving your coating services problems. We value the coating knowledge and application experience of our industrial coating services staff, who have decades of experience. Protect your high-traffic spaces with durable antimicrobial coatings. Contact Crest Coating today to learn more about our silver ion-infused solutions and how they can help prevent germ growth in your environment!